Many of you may see yourselves as chaotic.

Especially, if you are in an Agile industry, you are in a fast-paced environment.

Things can get overwhelming pretty easily. You may even be surrounded by dysfunctional teams that make staying on top of your work tiresome and difficult.

That is where Kanban methodology comes into play. It’s not the ultimate solution to structured workflow and organizational efficiency, but it is a means to an end.

Here is everything you need to know to answer the question: What is Kanban Agile?

Kanban vs Agile

Before we get into the details of Kanban, you may have noticed the question above, “What is Kanban in Agile?” The reason for this is the connection between the two.

In order to properly understand the Kanban method, it is important to be clear about its relation with Agile and what the differences are.

Agile project management refers to a group of methodologies that includes Scrum and Kanban.

Agile is focused on simultaneous workflows that are adaptive.

You may be searching for the differences between Agile and Kanban, but the truth is the Kanban method is a type of Agile methodology. Therefore, Agile vs Kanban can be misleading.

Kanban uses the Agile principles and implements them in its particular way.

How it manages to do this we will discuss below.

What is Kanban Methodology?

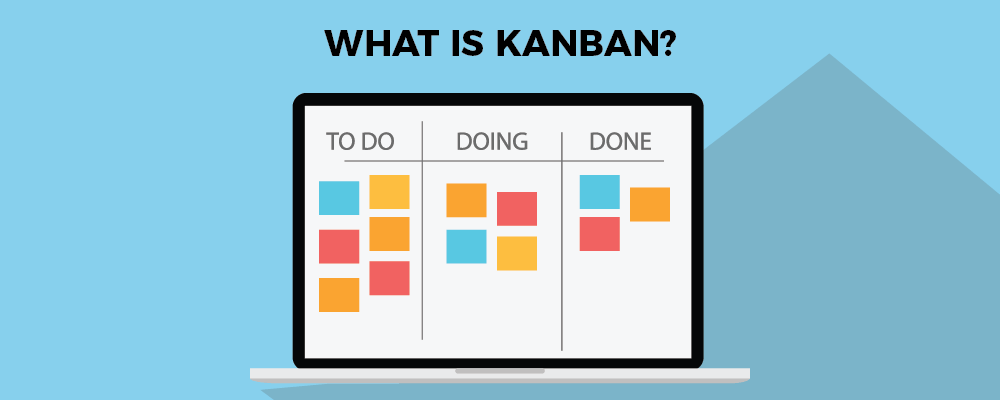

Kanban is an agile methodology and can be described as a work management system. This process is designed to visualize your work as it moves through a process.

By visualizing your work, you can limit work in progress while also maximizing efficiency. This lets your team work together more effectively.

A Brief History of Kanban

The first Kanban system was created by an industrial engineer and businessman of Toyota automotive in Japan. This businessman, Taiichi Ohno, developed Kanban as a planning system.

With a Kanban process in place, Toyota was able to achieve an efficient and flexible just-in-time production control system.

This system allowed them to increase their productivity while simultaneously reducing the cost of housing an intensive inventory of raw materials, partially finished materials and finished products.

Kanban systems help prevent overstocking and supply disruption of goods throughout the manufacturing process. This is because it controls the entire value chain, from the supplier to the end consumer.

Taiichi Ohno’s concept was adapted in 2004 by David J. Anderson. He applied it to software development, IT, and knowledge work in general.

Kanban Principles

The Kanban method observes a set of basic principles to help manage and improve the flow of work.

By following these principles, you will be able to use the Kanban system to maximize benefits to your business processes.

The four fundamental principles of the Kanban Methodology are as follows:

1) Start with What You do Now

The Kanban method does not require you to make any sweeping changes.

This method should be applied to your current workflow, systems, and processes. Thus, allowing what is being successfully done, to continue, but also highlighting any issues that need to be addressed.

Kanban’s flexibility and versatility let you introduce it incrementally. Thus, avoiding any resistance from your team, as well as any over-commitment that would otherwise jeopardize its implementation.

2) Agree to Pursue Incremental, Evolutionary Change

Following on from the previous principle, Kanban encourages incremental change. This method is aimed at meeting minimal resistance.

These small but continuous changes avoid creating fear or uncertainty among employees, and therefore also avoid potential resistance from the workforce.

3) Respect the Current Process, Roles, and Responsibilities

Kanban is set apart from other methodologies since it does not insist on any organizational modifications by itself.

Kanban simply allows you to see what is working, and where change needs to be implemented.

These problem areas can be identified and changes can be applied with the collaboration of the team.

Again, like the previous two principles, these rules ensure that you avoid any resistance or fear in your workforce that usually comes as a result of such change initiatives in an organization.

4) Encourage Acts of Leadership at All Levels

Kanban only works if everyone has a mindset of continuous improvement. This process cannot be sustained if it is to be kept as a management level activity.

As mentioned, Kanban encourages continuous improvement, at every level of an organization.

Improvements through the Kanban method can stem from ideas provided by people at all levels of the company.

Each member of a company can show leadership and implement changes that will allow them to continually improve how they deliver their outcomes.

Benefits of the Kanban Methodology

Kanban is a popular methodology adopted by agile teams, but why is that?

With Kanban, you can benefit not only in your task planning but also in the output provided by your teams.

Here are some of the advantages of using the Kanban method.

1. Identifying Bottlenecks

A key rule of Kanban is to limit work-in-progress. It is a common phenomenon in organizations to multitask. However, multitasking has been seen to be problematic especially in terms of efficiency.

The need to constantly switch between tasks and work can affect your task’s completion.

Limiting work-in-progress lets you and your team highlight any bottlenecks in your development process which could be because of a lack of focus, resources, or skills.

2. Flexibility

Kanban is flexible. There are no predefined phases. Priorities are reviewed according to the current situation of your processes.

As we mentioned, teams following the Kanban method are only focused on the work-in-progress.

The way the Kanban system works is that a team completes a work item. They then pick the next item from the top of the backlog.

This system allows product owners to prioritize the items in the backlog without impacting the team. Since any change outside of the work in progress won’t impact their current task.

This also gives product owners the chance to include the team in the entire process. You can collaborate with your team when considering changes to your backlog. This ensures there are no surprises and your team is delivering maximum value back to the organization.

3. Focus on Continuous Delivery

Continuous Delivery is the act of releasing work to customers frequently. Both Continuous delivery and Kanban integrate since they both focus on just-in-time delivery.

With continuous delivery, you can become more competitive with the product in the market.

This benefit of Kanban is reiterated by the fact that the system is focused on optimizing the flow of work delivered to the customer.

4. Shortened Cycle Time

The time it takes for an item of work to make its way through your team’s workflow is referred to as cycle time.

Cycle time is a key measurement or metric for a Kanban system.

By optimization of cycle time, you and your team can predict the delivery of your outcomes and work.

It is the whole team’s responsibility to make sure that work moves through the development process with efficiency.

You can shorten cycle times by working on the resources you hire. If you have a single resource that has a particular skill set, this can create a bottleneck in your workflow.

Overlapping skill sets are a way to shorten cycle times. Shared skills allow team members to take on diverse work. This also lets you optimize cycle time.

For example, if there is a delay or backup of work in your workflow, the onus of fixing the issue can be shared among team members and does not fall on the shoulders of anyone’s resource in particular. This allows work to start flowing smoothly faster.

5. Visual Metrics

Visual tools allow your team an overview that lets you see how you can continue to improve. By having that visual aid, you can identify bottlenecks easier and thus rectify them quicker.

Commonly adopted in Kanban systems, teams will use control charts and cumulative flow diagrams.

1. Control Chart

A control chart is used to view the cycle time of your process.

With a control chart, you map the time spent by each issue in a particular status over a specified time period.

You can use a Control Chart to:

- Measure how a change in process affected your team’s productivity

- Show a visual overview of your team’s performance to external stakeholders

- Analyze your team’s past performance retrospectively

- Use past performance to view targets for your Kanban team

2. Cumulative Flow Diagram

Cumulative flow diagrams let you and your team visualize effort and project progress.

The cumulative flow diagram indicates how tasks collect over time. The diagram also shows how these tasks are distributed among the different process stages.

Related:

64 Important Business Metrics Your Company Must Know

Kanban Practices

When you are implementing the Kanban method into the workplace certain practices can streamline the process.

David J. Anderson highlighted 6 practices that you need to follow as a team to make the implementation of the Kanban method successful.

We will go over each of these 6 practices in turn.

A. Visualizing the Flow of Work

The Kanban system uses visualization tools such as the Kanban Board, which we will discuss in detail later, to view tasks and the process tasks go through.

To make this visualization as effective as possible, you should include:

- The commitment point: where in your work process does your team agree to do a specific task

- The delivery point: where in your work process does your team deliver the item to your customer

- Any policies that determine what type of work or tasks are included in a particular stage of your process

- Work-in-progress limits.

B. Limit Work-in-Progress

A fundamental element to successfully implementing Kanban is by limiting work-in-progress.

This limitation encourages your team to focus on the work at hand and complete it before taking up new tasks.

Since this may be a drastic shift from your current working style, especially since multitasking is prevalent in many organizations, you may start with no work in progress limits and work into adopting them.

Start by observing the current system and the initial work in progress. Once you have gathered information about your processes, after implementing Kanban, you can define the limits that will work for your team.

This limitation not only helps with planning but also ensures the quality of the work you deliver while avoiding delays.

C. Managing Flow

Remember, Kanban is about managing the flow and not the people.

If you are confused with the concept of “flow”, understand it simply as the movement of work or tasks through your production process.

The main aim of Kanban and the reason organizations want to implement it, is to help smooth out and create a healthy flow.

You need to ensure you monitor your processes; this will help you understand how to move the work faster through your workflow.

Avoid micromanaging people and strive to deliver value quicker.

D. Make Policies Explicit

Ensuring you have explicit policies allows you to move beyond a simple listing of different workflow stages, and helps identify a process.

Any good policy should be:

- Simple

- Sparse

- Well-defined

- Readily adaptable

- Visible

- Always applied

Make sure that everyone understands the policies. Thus, allowing for a common goal.

E. Feedback Loops

Feedback loops are an important part of a system that wishes to provide evolutionary change.

Feedback loops are an essential step for any organization that wants to be more agile. Such a review ensures that teams and processes are responding to potential changes.

Early and continuous feedback is especially important if your team is on the wrong track. Such feedback is critical to delivering positive outcomes and successful products to customers.

With Kanban, you have feedback loops of various kinds, including:

- Service delivery reviews

- Strategy reviews

- Operations reviews

- Risk review meetings

- Daily stand up meetings

F. Improve Collaboratively, Evolve Experimentally

As we mentioned previously, the Kanban method applies continuous and incremental improvements to processes that already exist.

This is done through the use of a scientific method, that is forming a hypothesis, testing your theory, and making changes according to the outcomes of your test.

Therefore, your goal as a team should be to constantly evaluate your processes, and improve continuously, as needed, and however possible.

These changes should not be implemented and forgotten. It is important to monitor them and evaluate whether they are helping your team improve.

How Does Kanban Work? The Concept of a Kanban Board

Kanban is to visualize your workflow. This is done through a Kanban board.

Visualizing your tasks and workflow on a Kanban Board lets you better understand your processes while having an overview of you and your team’s workload.

This visual aid will let you be able to identify problem areas faster. Therefore, allowing you to work on the issues to get your team working more efficiently.

Jim Benson theorized a simple Kanban board, one that focuses on what Kanban rules are, namely, namely limiting work in progress and visualizing work.

He claims that “The more rules you add, the less context it fits into.”

On the other hand, David Anderson identifies five components every board should have.

1. Visual Signals

Kanban boards will have characteristic visual cards. These cards are used to write your team’s projects and work items. Usually, each card hosts one work item or task.

Once these cards are placed on the board, it gives team members, as well as other audiences to the board (like stakeholders), a visual signal as to what the team is working on.

2. Columns

Another distinguishing feature of such boards is the columns. You use columns in this kind of board to signify a specific activity when combined represent the workflow.

Since Cards represent tasks, they should flow through the columns (workflow), until they reach completion.

These columns can be as simple or as detailed as you like. For the most basic type, you can have three main columns or sections on your board. For example, to-do, in progress, and done.

3. Work in Progress Limits

By work in progress limits, we mean the limit of cards that can be in a single column at any given time.

This ensures that if a column hits its maximum capacity in regards to the work in progress limits you impose, your team should focus on moving those cards forward in the workflow. This has to be done before new cards can move into that stage of the workflow.

These limits are essential in identifying bottlenecks and maximizing flow.

These work in progress limits also provide you with an early warning if you have committed to completing work that is above your capabilities in regards to the resources you have.

4. Commitment point

The commitment point is when a proposal is picked up by your team and work is started on that project.

On that note, when we talk about the Kanban method, there is often a backlog document. This is where such ideas are put forth by team members or customers. Your team members will then pick these ideas up when they are ready.

5. Delivery point

The delivery point is the completion of the workflow. Usually, this is the moment in the workflow when the product or service is delivered to the customer.

The goal of your team should be to take cards through the workflow, from the commitment point to the delivery point, as fast as possible.

Lead time is the time elapsed between these two points. As a Kanban team, you should work towards decreasing this lead time as much as you can.

Kanban Tools

With the shift in work culture, more and more organizations prefer to house their information online to aid with collaboration among their team.

The same can be said for implementing a Kanban-style and system to one’s work.

One such way to manage this is by investing in a Kanban tool.

Certain project management tools incorporate Kanban and Agile methodologies into their features. Thus, allowing you to create virtual Kanban boards that can be accessed by your entire team with ease.

nTask’s latest update features such a Kanban tool. With this tool, you can customize your workflow and optimize your lean time.

With your entire project on a single platform being encompassed through visualization of the Kanban Board, your workflow and outcomes are bound to improve significantly.

Find more Kanban Tools here:

14 Best Kanban Tools To Use In 2024

Conclusion

There you go, the basics behind implementing the Kanban method.

With any such organizational implementation, more knowledge and greater understanding are always best.

Check out our other blog posts on the Kanban method that will help with this change in your company.